The goal of this research is to employ a systems perspective to strengthen decision-makers’ ability to predict the impacts of corporate and governmental policy in the materials substitution and recycling arenas. We are building market materials models of supply and demand that aid in understanding how to minimize material impact and reduce supply chain risk. To this end, we are developing the analytical capability to inform firm/industry strategies as to screening for materials availability risks; recycling costs and environmental impacts; and identifying substitution threats to incumbent and opportunities for new materials.

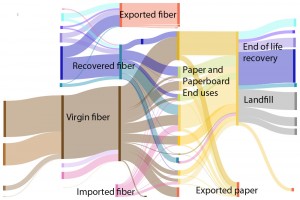

Understanding the environmental impact of wood fiber recovery and reuse

This project is developing analyses to educate stakeholders and support decision making around recycled paper and other recovered fiber supply chains in conjunction with the American Forest & Paper Association. The project motivation stems from a desire to understand the impacts of fiber recovery and use along a variety of metrics including economics, and greenhouse gas emissions. Our analysis employs a consequential life cycle assessment methodology coupled to a partial equilibrium model based approximately on fiber recovery markets.

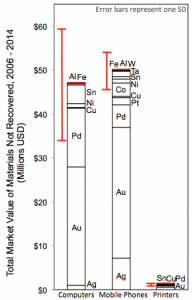

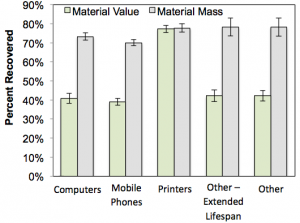

Economics of End-of-Life Materials Recovery

The challenges brought on by the increasing complexity of electronic products, and the criticality of the materials these devices contain, present an opportunity for maximizing the economic and societal benefits derived from recovery and recycling. Small appliances and compute devices (SACD), including mobile phones, contain significant amounts of precious metals including gold and platinum, the present value of which should serve as a key economic driver for many rec ycling decisions. However, a detailed analysis is required to estimate the economic value that is unrealized by incomplete recovery of these and other materials, and to ascertain how such value could be reinvested to improve recovery processes.

ycling decisions. However, a detailed analysis is required to estimate the economic value that is unrealized by incomplete recovery of these and other materials, and to ascertain how such value could be reinvested to improve recovery processes.

We present a dynamic product flow analysis for SACD throughout Portugal, a European Union member, including annual data detailing product sales and industrial-scale preprocessing data for recovery of specific materials from devices. We employ preprocessing facility and metals pricing data to identify losses, and develop an economic framework around the value of recycling including  uncertainty. We show that significant economic losses occur during preprocessing (over $70M USD unrecovered in computers and mobile phones, 2006-2014) due to operations that fail to target high value materials, and characterize preprocessing operations according to material recovery and total costs.

uncertainty. We show that significant economic losses occur during preprocessing (over $70M USD unrecovered in computers and mobile phones, 2006-2014) due to operations that fail to target high value materials, and characterize preprocessing operations according to material recovery and total costs.

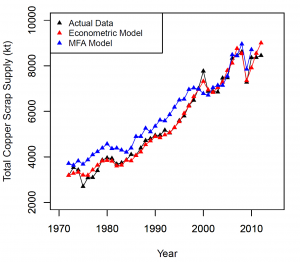

Econometric modeling of recycled copper supply

The supply of recycled metal depends on historic consumption, i.e. what constitutes scrap today was used to make products in the past. Many modeling techniques, such as materials flow analysis, use this observation to estimate scrap metal flows. However, the supply of scrap metal also depends on changing economic conditions.

The supply of recycled metal depends on historic consumption, i.e. what constitutes scrap today was used to make products in the past. Many modeling techniques, such as materials flow analysis, use this observation to estimate scrap metal flows. However, the supply of scrap metal also depends on changing economic conditions.

In this project we are using econometric models coupled with material flow analysis to model the supply of recycled copper. We have found that both industrial activity, as measured by an industrial production index, and demand from electrical equipment, appliances and component (EEAC), as measured by EEAC Production Index are positively correlated with copper scrap supply. We also are investigating how these drivers change as a function of scrap quality. We find that higher quality copper scrap supply is driven mainly by the level of industrial production in developed countries, while lower quality copper scrap supply is driven mainly by income growth rate and level of mining activities. A recycling policy aimed at increasing recycling through the use of subsidies, taxes and other price incentives should therefore be directed towards the low-end segment of the scrap market where they can have the greatest effect.

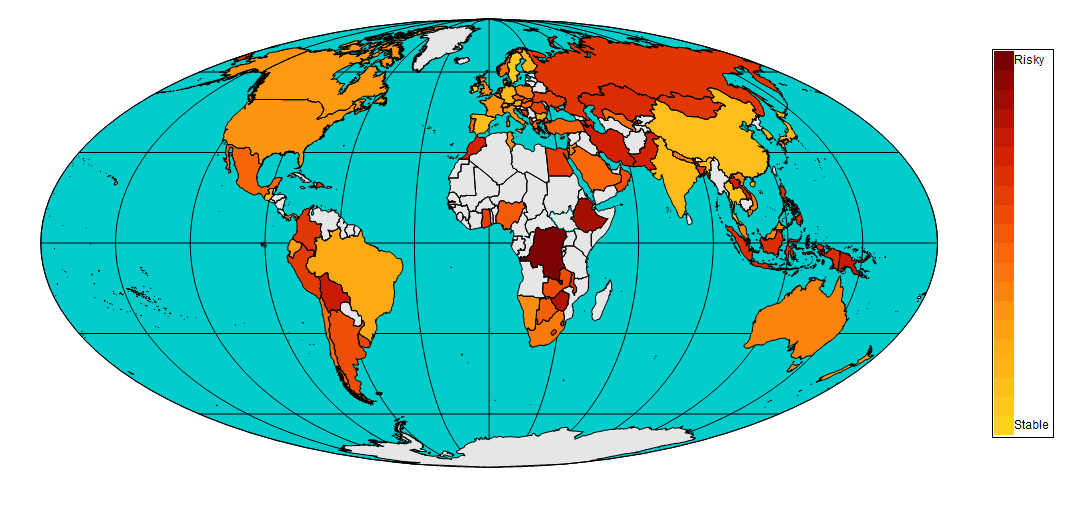

Method of determining national level metal supply risk

Metals are important for modern society, and metal products in all phases of their life cycles are traded globally to meet the demand of different countries. Due to difference in mineral deposit and economic conditions, some countries may suffer from lack of reliable metal supply sources.

Metals are important for modern society, and metal products in all phases of their life cycles are traded globally to meet the demand of different countries. Due to difference in mineral deposit and economic conditions, some countries may suffer from lack of reliable metal supply sources.

In this study, we develop a method which calculates supply risk based on stability of suppliers and supply concentration. From a case study on copper, we find that a country’s supply risk in the mining, smelting and refining stage is highly correlated. Three major sources are found to drive high supply risk, namely low economic development, lack of sources of import and heavy reliance on metal industry in national economy. In response to high supply risk, governments could carry out policies that aim at managing risk, such as creating economic incentives to improve technical efficiency and require end-of-life recycling.

Technology Evaluation & Strategy Formulation for Scrap Steel

Recent technological development offers a great opportunity to recover valuable materials from waste. However, the economic and environmental benefits of using these technologies are often contextual. This research aims at developing a framework to support decision making in steel recycling.

We are developing an analytical tool that quantifies the impact of various material separation technologies on economic values and quality of steel scrap. This tool will help steel recyclers to choose a set of technologies that can bring the most value to the firm.