The increased use of secondary (i.e., recycled) and renewable resources will likely be key in achieving sustainable materials use. Unfortunately, these strategies share a common barrier to economical implementation – increased quality variation compared to their primary and synthetic counterparts.

With this project, we are working to reduce energy use and greenhouse gas emissions associated with the construction industry by introducing alternative materials derived from unused or currently underutilized industrial wastes and byproducts.

Beneficial Use of Non-Hazardous Industrial Byproducts in Building Materials

Industrial activity leads to significant environmental impact in the form of energy use and emissions to air, land, and water. As one of the largest consumers of natural resources and emitters of greenhouse bases, the construction industry is rife with opportunities for impact reduction.

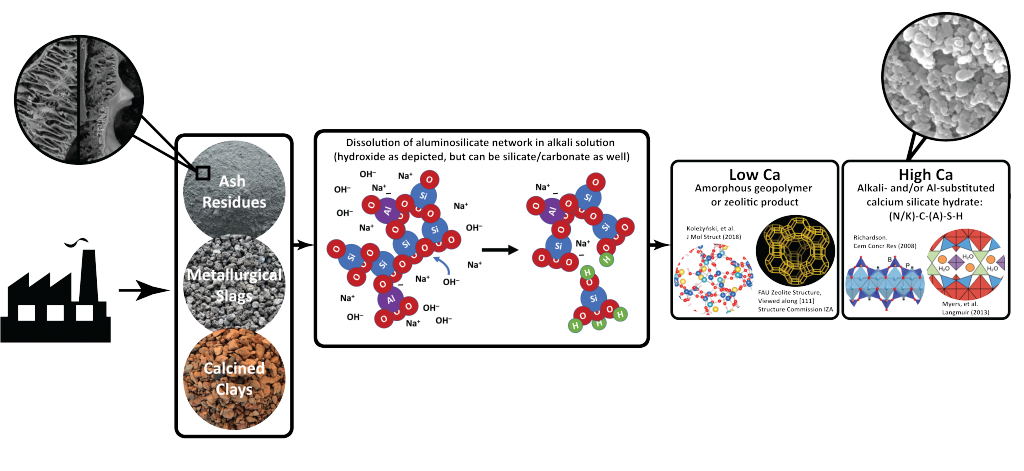

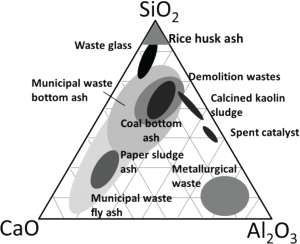

Growing global industrialization and urbanization combined with increasingly apparent impacts of global climate change make such research into industrial alternatives imperative. To that end, we are developing novel construction materials based primarily on alkali-activation and geopolymerization of industrial byproducts. Alkali-activation – the reaction of aluminosilicate precursors, such as ashes, clays, and metallurgical slags, with alkali-rich aqueous solutions – affords us the opportunity not only to divert such aluminosilicates from landfill, but also to reduce reliance on conventional building materials, such as cement and fired-clay bricks, which exhibit inherently large environmental footprints.

This approach addresses both the environmental impact of byproduct generation and the status quo practices associated with resource use in the built environment. Our research combines expertise in materials science, environmental and economic assessment, architecture, and civil engineering.

Materials and Methods of Focus

Our work has focused on the chemical analysis of such materials for the purpose of gaining a deeper understanding of material reactivity. This has involved raw materials and reaction product characterization through XRF, FTIR, XRD, NMR, and N2 adsorption (BET), amongst other methods. Dissolution studies of raw materials, as monitored by ICP-OES, have proven useful as a method for understanding reactivity and elemental availability.

Biomass ash:

A major focus so far has been alkali-activation of boiler ash derived from partial combustion of agricultural residues (e.g., rice husk, bagasse, and wood chips). Across the developing world, unreliable and expensive electrical grids incentivize on-site energy generation by industrial plant owners. While large plants primarily burn coal, small and medium-sized paper, rice and sugar mills ban cheap agricultural residues, which vary by both season and locale, and yield ashes that are similarly variable. As a result, biomass-derived boiler ashes are generally underutilized and generate multi-ton daily landfill burdens.

A major focus so far has been alkali-activation of boiler ash derived from partial combustion of agricultural residues (e.g., rice husk, bagasse, and wood chips). Across the developing world, unreliable and expensive electrical grids incentivize on-site energy generation by industrial plant owners. While large plants primarily burn coal, small and medium-sized paper, rice and sugar mills ban cheap agricultural residues, which vary by both season and locale, and yield ashes that are similarly variable. As a result, biomass-derived boiler ashes are generally underutilized and generate multi-ton daily landfill burdens.

Through collaboration with partners in northern India, our work has resulted in the pilot-scale production of biomass ash-derived bricks, with calcium silicate hydrate as the primary reaction product. While these bricks have long adhered to the Indian standard for unit strength, current work is focused on meeting water absorption standards.

Metallurgical slags:

The steel and copper slag industries produce massive quantities of slag – 190-290 and 15-25 million metric tons in 2018, respectively. These slags are largely underutilized or used in low-value applications due to their crystallinity and high chemical variability. Designing new building materials that incorporate industrial wastes with variable composition requires a strategy that allows for this variability to be accounted for during mix design from one slag to the next. Our focus is on understanding the reactivity of these slags through studies of their constituent phases. Differences in phase composition between slags can then be more easily translated to differences in their reactivity. By studying the reactivity of these phases in a range of different aqueous chemical environments, the most appropriate re-use pathway for these wastes can also be identified, e.g., in alkali-activated materials or blended with Portland cement.

The steel and copper slag industries produce massive quantities of slag – 190-290 and 15-25 million metric tons in 2018, respectively. These slags are largely underutilized or used in low-value applications due to their crystallinity and high chemical variability. Designing new building materials that incorporate industrial wastes with variable composition requires a strategy that allows for this variability to be accounted for during mix design from one slag to the next. Our focus is on understanding the reactivity of these slags through studies of their constituent phases. Differences in phase composition between slags can then be more easily translated to differences in their reactivity. By studying the reactivity of these phases in a range of different aqueous chemical environments, the most appropriate re-use pathway for these wastes can also be identified, e.g., in alkali-activated materials or blended with Portland cement.